The terms “reefer container” and “reefer” are short for “refrigerated container.” These containers maintain a stable temperature inside while controlling humidity and promoting adequate airflow. The reefer shipping container’s climate control functionality keeps the products inside from spoiling, which may occur from too much heat, excessive moisture, not enough airflow or temperatures that drop too low.

Table of Contents

- How Does a Reefer Container Work?

- How Does a Reefer Container Work as a Shipping Container?

- How Does a Refrigerated Container Work for Storage?

- What Are the Components of a Reefer Container?

- Packing a Reefer for Optimum Climate Control

- What Is a Reefer Container Used For?

- What Is the Capacity of a Reefer Container?

- How Do You Set the Temperature on a Reefer Container?

- How Much Does a Reefer Container Cost?

Temperature-sensitive materials, such as food and pharmaceuticals, require careful reefer container temperature control during shipping — a feat accomplished through the use of reefers. So how are reefer containers powered? Cold chains, or the process of storing and transporting goods at proper refrigeration temperatures, include multiple steps to get supplies from their origin to their destination while keeping the perishable goods fresh. Refrigerated containers are a vital part of this chain and offer a solution that typically provides temperature ranges from -30°C to +25°C. Without these reefers, international shipments of temperature-sensitive products would be impossible.

Reefer containers have decades of use transporting delicate materials that could go bad during shipping. The international cold chain allows the U.S. and other countries to keep cold products fresh and in good condition during an ocean-crossing. Reliable temperature-sensitive transportation gives the U.S. and countries around the world the chance to grow their export markets while also meeting the growing demand for fresh and local foods. Refrigerated containers help with this goal, as they are trusted storage and transport containers.

How Does a Reefer Container Work?

Refrigerated containers work both for storage and transport. In either case, the goods inside — whether chemical, food or pharmaceutical — must have consistent climate control.

1. How Does a Reefer Container Work as a Shipping Container?

When shipping, reefer container operation is typically run on vessel or shore power.

During rail or truck shipping, a generator provides portable power to the reefers. Containers may have a built-in generator, or they may have one externally located.

The floor of the refrigerated container has a “T-floor” to allow for airflow under the cargo. Cold air blows from the refrigeration unit through the vents at the bottom of the reefer and all the way to the back doors. The warm air at the top of the container flows back to the refrigeration unit over the cargo, where it chills for return to the interior. It is vital that proper loading is observed to prevent “chimneys” or short-cycling of this airflow and that the entire floor of the reefer container is covered during transport, at least by approved dunnage or heat-treated plywood covering if cargo pallets are not available to fill the entire container. Careful placing of containers to allow air to flow between them ensures this operation continues without problems.

For fruit transport, the air movement also allows for fresh air to cycle in as carbon dioxide and ethylene gas-filled air moves out of the reefer, preventing premature spoilage of the fruits.

2. How Does a Refrigerated Container Work for Storage?

Refrigerated containers also work for temporary storage as long as they have a power source to operate the cooling unit. Whether it is storage during an emergency, while a damaged reefer undergoes repairs or to keep surplus products while awaiting shipment, refrigerated containers work just as well for storage as they do for shipping.

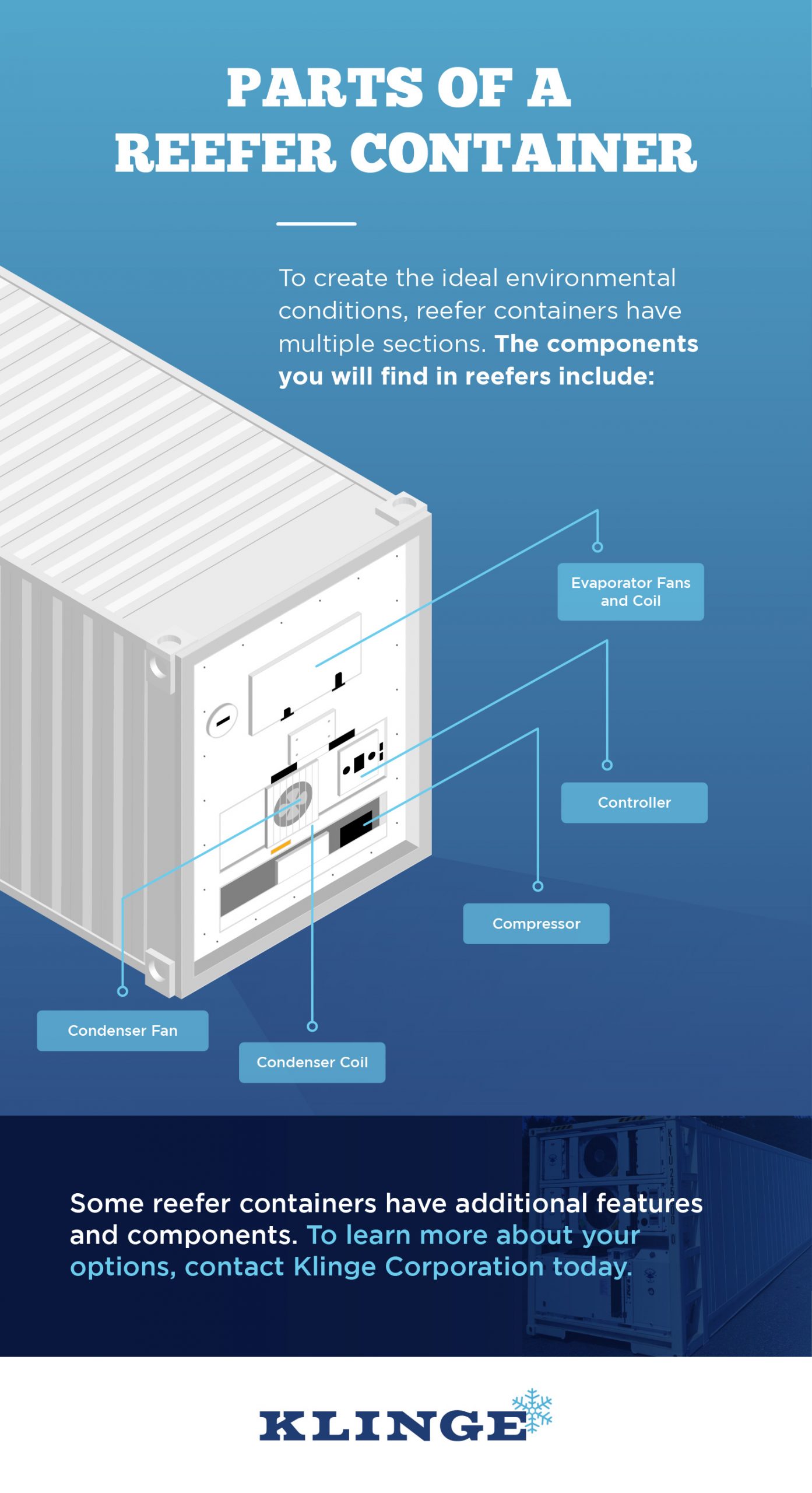

3. What Are the Components of a Reefer Container?

To create the ideal environmental conditions, reefers have multiple sections, many of which dry containers lack. The components you will find in reefers are the interior fans, control unit, fresh air vent, the unit evaporator and the condenser section. Some reefer containers also have heating capacity using either hot gas heat or electrical heating elements. These operate together to maintain the temperature inside the container and in most standard reefers are all combined into one single reefer unit, which fits onto the end of the insulated reefer container body. They are not intended to cool a warm cargo load (though they will eventually in most cases) but are intended to keep frozen or cold foods or medicines at stable temperatures.

Reefer container components include:

- Interior fans: Interior fans located inside the reefer help circulate air to promote adequate temperature control and stability.

- Control unit: The control unit allows you to set and adjust the internal atmosphere of your reefer, including the temperature, alarm conditions, and in some cases ventilation and humidity levels.

- Fresh air vent: The fresh air vent allows air to enter from outside and any gases from in the container, such as fruit-ripening ethylene gas, to leave.

- Unit evaporator: Excess moisture in a reefer can damage products, quicken food spoilage and break down packaging, leaving contents vulnerable. The unit evaporator helps maintain the moisture inside the container. The reefer unit evaporator can either heat or cool the air that circulates past it from the fan. Sometimes, the reefer will need to warm the air to keep the interior temperature consistent, which is either done using hot gas heat or electrical heating elements. Reefers can maintain temperatures up to 30 degrees Celsius (86 degrees Fahrenheit). Whether it heats or cools the air depends on the desired internal temperature.

- Condenser: Condensers may have air or water cooling, though typically, the industry is using air-cooled condensers. Air-cooled models pull cooled air from the top of the container and discharge it under the cargo, pushing the air to the back doors before it convects naturally and rises, flowing back over the cargo to the return air inlet on the reefer unit. Because air moves under the cargo, proper loading and covering as much of the floor as possible is critical to prevent a “chimney” effect and short-cycling.

- Voltage transformers: Dual voltage transformers are also an option with some containers, allowing operation on voltages down to 200V 3ph.

There are a variety of reefer shipping containers, some of which have additional features and components, such as remote monitoring or specially constructed frames, to prevent explosion when transporting sensitive materials. To ensure efficient reefer operation, schedule regular inspections and servicing appointments for your unit, especially before long cargo trips. Never use a reefer if any components are malfunctioning.

Genset: When reefer units are transported on land, where they don’t have access to power like in the ports or on the vessel, they rely on a genset for power. What is a genset on a reefer container? Much like “reefer” is a shortened form of “refrigerated container,” “genset” means “generator set.” It provides the necessary power for a reefer to operate efficiently. Two types of gensets on reefers include clip-on gensets — which are attached to the front or side of the container — and underslung gensets, which go underneath the frame. In addition, companies such as Klinge provide gensets which are built directly into the container, which means that special chassis with gensets or other logistics arrangements for clip-on gensets are not necessary.

4. Packing a Reefer for Optimum Climate Control

How you pack a refrigerated container determines how well it keeps the products inside at a constant temperature without hot and cold spots.

Inside a reefer, to allow for proper air movement, goods should not hang over any pallets. The boxes should have vents to allow for vertical airflow from the bottom of the container. Align all vent holes in boxes to keep air moving as smoothly as possible, and do not stack boxes until they touch the ceiling, but observe the internal load line limits. Allow for air to move between the roof and the top of the boxes.

Since the goods in a refrigerated container must be kept cool, it’s optimal to use a dedicated cooling facility where the goods are pre-cooled before they are loaded into the reefer. It is often more feasible and energy-efficient to pre-cool the goods than to pre-cool the reefer — if a reefer is pre-cooled, the facility in which goods are loaded into it also needs to also be pre-cooled and temperature-controlled. This is often not possible, which is why pre-cooling the reefer before loading goods would be wasted energy. Pre-cooling will also lead to ingress of warm, moist air into the cold reefer container, causing excess development of moisture and unnecessary defrost cycles, further reducing the ability of the reefer container to cool the product after efficiently after loading.

It is also vital that pallets loaded into the container are completely dry in order to avoid these same defrost issues.

Frequently Asked Questions About Reefer Containers

Reefer containers are an integral part of many companies’ ability to ship and receive valuable goods. Learn more about reefer containers and how they work with the answers to these frequently asked questions.

What Is a Reefer Container Used For?

Refrigerated containers are used for fresh flowers, fruits, meats, dairy, vegetables, pharmaceuticals and chemicals/dangerous goods. These goods can stay fresh or frozen as required in climate-controlled reefers that can reach temperatures as low as -60 degrees Celsius (-76 degrees Fahrenheit).

What Is the Capacity of a Reefer Container?

Reefer container capacity varies, depending on the contents you are storing or shipping, the age of the unit and the manufacturer. Some products, such as small batches of medicine or pharmaceutical supplies, require minimal space, while large shipments of produce and hazardous chemicals need ample room for safe storage. Though containers are typically 20 or 40 feet long, the total space inside is less than the exterior due to the refrigeration equipment taking up some of the room inside the container. At Klinge Corporation, we offer standard refrigerated containers in both 20-foot and 40-foot configurations, but additional sizes are available depending on the specific type of container you require. Contact a Klinge Corporation representative to learn more.

To determine the required capacity for your shipment, consider the type and size of your products, including the size of the packaging and shipping materials, as well as how much space each item requires for safe transport. When you are sizing materials for accurate dimensions, include their height, weight and width and compare those measurements to the reefer’s volume and dimensions.

How Do You Set the Temperature on a Reefer Container?

Temperature controls are the most important part of a reefer container. Without this function, the reefer would be unable to maintain a safe holding temperature for food, medicines and chemicals inside. This could result in costly waste or even dangerous reactions.

You can set the temperature and other critical settings for your reefer by using the control unit located on the outside of the container. While every manufacturer’s control unit varies, the basic steps are as follows:

- Make sure the reefer container is receiving power from either a power cord or genset.

- Turn the reefer unit on and wait for the unit to finish its start-up functions and self-tests. Should the reefer display an error message, do not continue using it or storing products inside.

- Using the marked buttons, set the temperature for the inside of your reefer unit and confirm when you are finished.

To determine the correct temperature for your items, consider the following:

- The type of item you are transporting and the temperature it requires to arrive at its destination safely.

- The traveling distance and conditions along the shipment route.

- Whether you need a continuous set temperature or a cycled defrost temperature.

- Specific client, company of regulatory requirements or quality standards.

Always have a temperature monitoring system in place to make sure your reefer container is working properly during shipment and that all items are being stored or shipped at the correct temperature. If you’re not sure how to operate your control unit or access different temperature settings for your container, consult the user manual, or contact the manufacturer for further guidance and instruction.

How Much Does a Reefer Container Cost?

The cost of a reefer container varies, depending on the manufacturer, size and type of container. When purchasing a reefer container, consider these factors:

- Size: Make sure the size of your chosen reefer container is large enough to accommodate your existing needs, as well as any future products you might be shipping or storing.

- Condition: You can purchase a used reefer through a used equipment supplier or buy a new unit directly from a manufacturer. If you choose to buy a used container, have a professional inspect it for operation and condition before purchasing.

- Type: Different types of refrigerated containers serve different purposes, so choose the right one before investing. Klinge Corporation carries dual refrigerated containers, ultra-low temperature refrigerated containers, offshore DNV containers, explosion-proof refrigerated containers and military refrigerated containers.

- Features: Some reefer containers have additional built-in features to maximize efficiency and safety, such as remote monitoring capabilities, internal gensets and explosion-proof reefer units.

- Manufacturer: Always consider the manufacturing company before investing in a reefer container for your product or business. Read about the company and their industry experience, including any available testimonials for quality and service. Make sure they provide the correct type and size reefer container for your needs.

If you need a reefer container for one-time use, you could also consider renting a new or used unit to meet your needs. If you choose to rent rather than purchase, it’s essential that you consider your supplier as carefully as you would if purchasing.

Contact Us for the Reefer Containers Your Company Needs

Reefer containers play critical roles in food and medicine shipments around the world. Many companies use them for transport. As leaders in the refrigerated container field, we can help you find the best options for shipping whatever you produce. Contact us at Klinge Corporation if you would like durable, trustworthy reefers that have options such as back-up chillers and more to ensure your shipment arrives in good condition.