Data loggers are essential to many different industries because of their data collection and storage abilities. These devices help companies track various environmental parameters and ensure certain conditions are being met. For example, data loggers are very commonly used in pharmaceutical products. With these devices, a company can monitor their products’ temperature and humidity, assisting them as they make sure their pharmaceutical goods are in a safe environment.

Table of Contents

- What Is a Data Logger?

- How Do Data Loggers Work?

- What Is a Data Logger Used For?

- Data Loggers in the Pharma Industry

- What Other Industries Use Data Loggers?

- Choose Klinge Corporation for Your Data Logger and Reefer Needs

What Is a Data Logger?

Data loggers are a type of electronic device made to store and collect data on environmental parameters over time. These devices monitor and record any changes to a designated area to allow users to properly measure, document, analyze and validate various results. Common parameters data loggers monitor include humidity and temperature. These devices also have a once per second or slower sample rate.

When you look for data loggers, you can find stand-alone units or those featuring multiple channels. Many stand-alone units run on battery power, making it possible for them to record parameters while they’re in transit and over long periods. Some data loggers can also work via direct DC power.

How Do Data Loggers Work?

Data loggers utilize a sensor to gather data, a microprocessor to perform various operations and internal memory to store data. While many data loggers come with a sensor built in, some may have universal inputs that allow users to install their own sensors. Once installed, a data logger will collect relevant data automatically.

Data loggers may only give users the option to see collected data on a local interface. They may also have wireless functionality, allowing other devices to connect to them. Other data loggers will transfer data to a computer where users can utilize software to see the collected data and analyze it.

The factors data loggers can measure vary based on their input types. A single input data logger will only provide one measurement, while multichannel data loggers have multiple inputs, allowing for more measurements. For example, a single input data logger may only measure pressure, whereas a multichannel input may measure humidity, temperature and pressure.

Some of the primary types of inputs include:

- Current: You can find many types of AC and DC data loggers. Companies usually utilize current data loggers to keep an eye on building equipment.

- Humidity: Humidity data loggers gather data on water vapor concentration, humidity and dew point. These measurements come in metric or standard units.

- Voltage: Voltage data loggers specialize in collecting data on any voltage measurements. Some of the most common voltage measurements include load to force and pressure to torque.

- Temperature: Many companies use temperature data loggers to measure extremely low or high temperatures. These data loggers can also measure liquid temperatures.

- Pressure: Pressure data loggers are designed to measure liquid and gas pressure. Some of these measurements include water and atmospheric pressure.

What Is a Data Logger Used For?

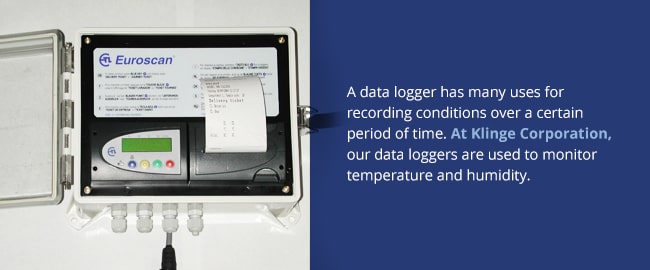

A data logger has many uses for recording conditions over a certain period of time. At Klinge Corporation, our data loggers are used to monitor temperature and humidity. One of the primary data logger advantages is its ability to measure various factors during transit without requiring any human intervention.

Companies also enjoy how they can change their measurement frequency to better meet their needs. For example, a company may decide to set their data logger to capture data further apart to increase the recording duration. In contrast, others may set their data logger to capture data in closely spaced intervals to gather data about transient events.

Another benefit of these devices is how easy it is for users to transfer data into a computer for formatting and analysis. Due to these devices’ compatibility with computers, a team doesn’t have to take manual measurements or input them manually into a software program. Since these devices automatically measure data once installed, they free up your staff for other tasks. You can also trust them to provide accurate data without risk of human error.

Data Loggers in the Pharma Industry

Data loggers are now widely used in the pharmaceutical industry. With electronic sensors and the latest measurement technologies, a pharmaceutical company can forgo paper charts. Process validation is crucial for drug manufacturers, so they have a significant need for instruments that can gather and preserve data.

Data logging in pharma is used for logging and verifying readings and basic parameters, such as the humidity and pressure during process operations. Depending on the process, certain parameters may need to be constantly monitored and logged, such as liquid levels, pH, equipment vibration, blend uniformity and operator activity.

Collecting and storing as much data as possible is essential for pharmaceutical manufacturers, making data loggers invaluable in this industry. Devices are also becoming more affordable, improving communication functions and offering more memory and lower requirements for power. You can use the data loggers from Klinge Corporation in your products to monitor temperature and humidity.

What Other Industries Use Data Loggers?

In addition to data loggers’ use for the pharmaceutical industry, you can find them in several industries supporting various applications. Since they can have many different kinds of inputs, companies can easily select a data logger perfect for their needs. Some of the main industries using data loggers include the following:

- Medical: Those in the medical industry face many strict regulations governing the proper storage of vaccines and medical devices. Given these regulations and the need to protect patients, many medical organizations outfit their refrigerators and freezers with data loggers to ensure vaccines and other materials stay at safe temperatures. The medical industry also uses data loggers for autoclave validation, as this validation ensures materials and equipment are sufficiently sterilized.

- Food: When food isn’t stored properly, it can spoil. As a result, many organizations in the food industry utilize data loggers to monitor their perishable foods. You can find data loggers used in every stage of the manufacturing process, with these devices monitoring temperature during cooking, storage and shipment. These data loggers will typically gather information on humidity and temperature and are often installed in refrigerated containers.

- Automotive: Since the automotive industry has to comply with various vehicle emissions regulations, data loggers are essential for meeting these rules. Many automotive companies utilize data to determine their vehicles’ emissions, helping them avoid fines and produce more environmentally friendly vehicles.

- Farming: Farming companies utilize data loggers to gather a variety of data to help them grow crops and better manage their food sources. Farmers regularly use data loggers to record hydrographic conditions, such as depth, pH levels, water level and flow. You can also find these devices employed for weather monitoring to assist with crop growth.

Choose Klinge Corporation for Your Data Logger and Reefer Needs

At Klinge Corporation, we manufacture and repair reefer containers that can help your pharmaceutical company transport goods. Since we know how important temperature control is for your industry and the goods you transport, we ensure our containers feature a dual refrigeration design and a backup power supply. We also regularly outfit our containers with data loggers so you can have in-depth information about your goods and know when a temperature falls out of an acceptable range.

Find out more about our data loggers today. To get data loggers that are essential for the pharma industry, contact one of our specialists or request a quote.