One of Klinge’s customer’s recently provided the below information about how their Klinge Quick Thaw Unit (QTU) helped to greatly reduce their processing time and production efficiency.

PREVIOUS PROCESS:

In the past, we used a 3rd party storage company where we rented 2 storage rooms. A smaller 30-pallet room in which we tempered beef and a larger room in which we would temper poultry and pork.

These rooms were kept at 40 degrees F (4°C) with fans left on at all times. They would stack the product adding spacers and turning one pallet in storage into two pallets for thawing.

The product would be put into the rooms ranging from the shortest being 5 days for most beef items to 28 days for most poultry and pork items. The number of days would also fluctuate based on seasonality and how much product was already in the room. The end results were products that were over/under-tempered for our process because of this fluctuation, making production less consistent. Then the warehouse would double stack to ship to our location which if product was over-tempered would create tipping issues inside the truck.

NEW PROCESS WITH KLINGE QUICK THAW UNIT:

We place orders at our 3rd party to add spacers into the required product for production. They add spacers the day before, they keep the same configuration height so there are no tipping issues.

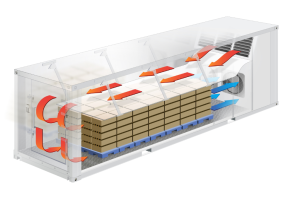

protein and final product in which we will use in and it is great that no one has to actively monitor the unit when in use. We load the product still in boxes placing the core probe, surface probes properly, and start the process. Most products only stay in QTU for 24 hours then the product is removed the next day in the early morning to get the QTU ready for next load. For most items, we bring product from frozen to about 28°F to 29°F (-2.2°C to -1.6°C)

We do have some processes where we bring product from frozen all the way to 32°F (0°C). When going to 32°F (0°C), the process might take a few more hours so we will run additional time over the 24 hours at times. With product being in boxes we temper roughly 20,000 lbs at a time, 10 pallets.

The QTU is saving us both time and money!